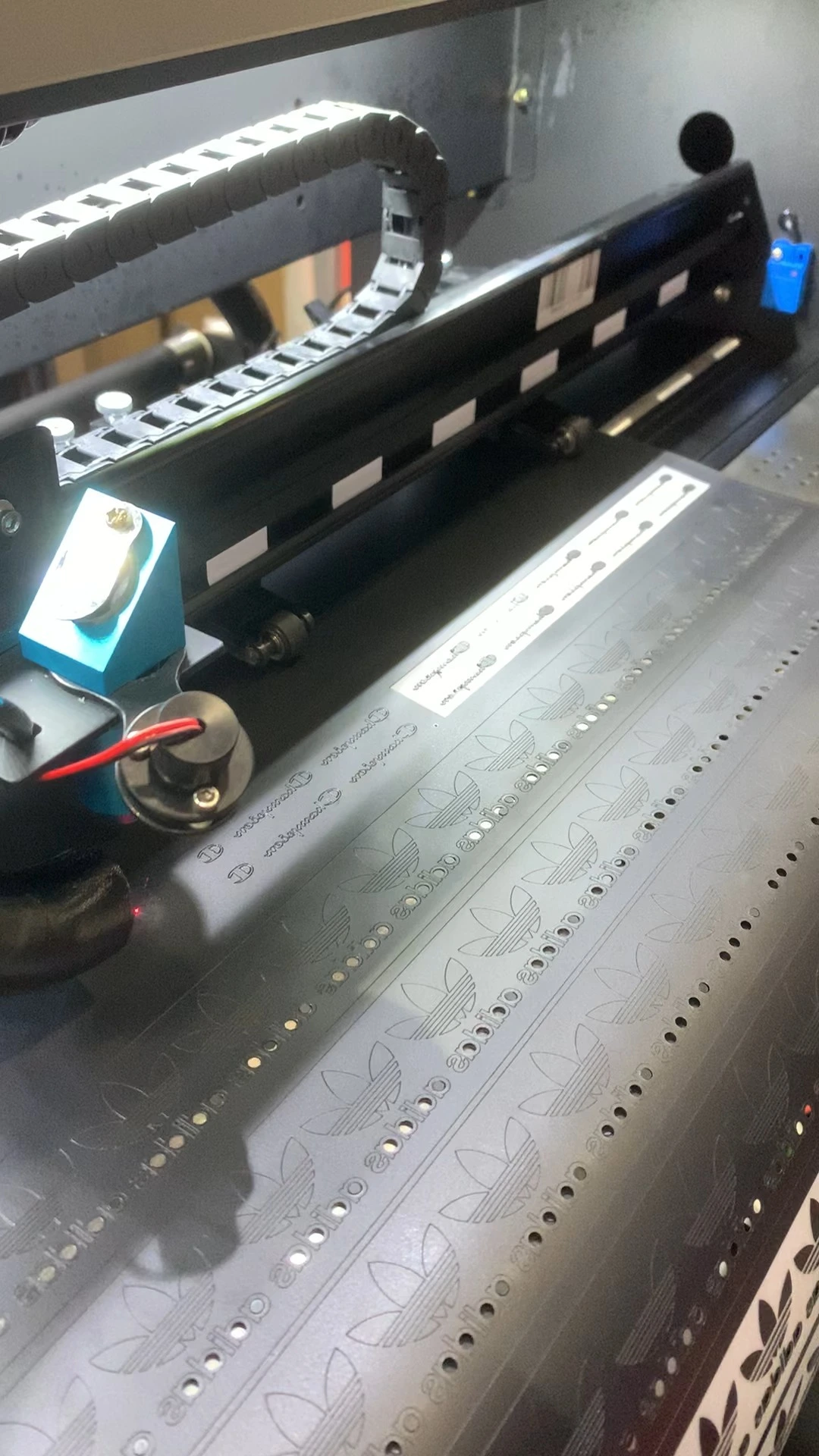

RF 45w laser cutting machine for T-shirt logo

### Advantages of Using an RF Laser Machine for Cutting 1.8mm Heat Transfer Vinyl for T-Shirts

1. **Precision and Accuracy**:

- **High Precision**: RF laser machines offer excellent precision, which is crucial for cutting intricate designs and detailed patterns on heat transfer vinyl.

- **Consistent Quality**: With RF laser technology, you achieve consistent cuts with smooth edges, eliminating the risk of frayed edges that can occur with manual cutting methods.

2. **Efficiency**:

- **Fast Cutting Speed**: RF lasers can cut through materials quickly, greatly increasing production efficiency and reducing the time taken to fulfill orders.

- **Batch Processing**: The ability to queue and process multiple designs or pieces at once enhances throughput, essential for high-volume operations.

3. **Material Compatibility**:

- **Versatility**: RF laser machines can handle a wide range of materials including different types of HTV, which can vary in composition and thickness.

- **No Material Deformation**: Unlike some other cutting methods, laser cutting does not physically contact the vinyl, reducing the risk of material distortion.

4. **Clean Edges**:

- **Sealed Edges**: The laser heat can help seal the edges of the vinyl, preventing peeling or curling, which is crucial for maintaining the longevity of the design on the T-shirt.

5. **Design Flexibility**:

- **Complex Designs**: The controlled manner in which an RF laser operates allows for the creation of complex and intricate designs that may be challenging to achieve with traditional cutting methods.

- **Ease of Customization**: Quick setup for different designs allows for easy customization aligned with customer preferences.

6. **Reduced Waste**:

- **Minimal Material Loss**: Precision cutting reduces waste material, which can lead to cost savings and a more environmentally friendly process.

- **Optimal Nesting**: Software tools often accompany RF laser machines, helping to optimize the layout of designs to further reduce waste.

7. **Low Maintenance and Operational Costs**:

- **Long Lifespan**: RF lasers have a long operational life with relatively low maintenance requirements, ensuring reliability and cost-effectiveness over time.

- **Energy Efficiency**: Technological advancements make modern RF lasers more energy-efficient compared to older systems.

8. **Ease of Use**:

- **Intuitive Software**: Many RF laser cutters come with user-friendly software, making it easier to design, edit, and process cutting files with minimal learning curve.

- **Automated Features**: Automation in modern RF laser machines simplifies setup and operation, even more, making it accessible to operators with varying skill levels.

Contact Person: Caroline Zhang

Tel: +86-188 1829 6536

WhatsApp: +86-188 1829 6536

ADD:

Room 1603-1605, bldg #1,no.1318 qixin road,shanghai,china